Reliability-based design optimization of a hydrogen vessel

Reliability-based design optimization of a hydrogen pressure vessel under operating condition uncertainty via a parametrized component-based reduced basis model

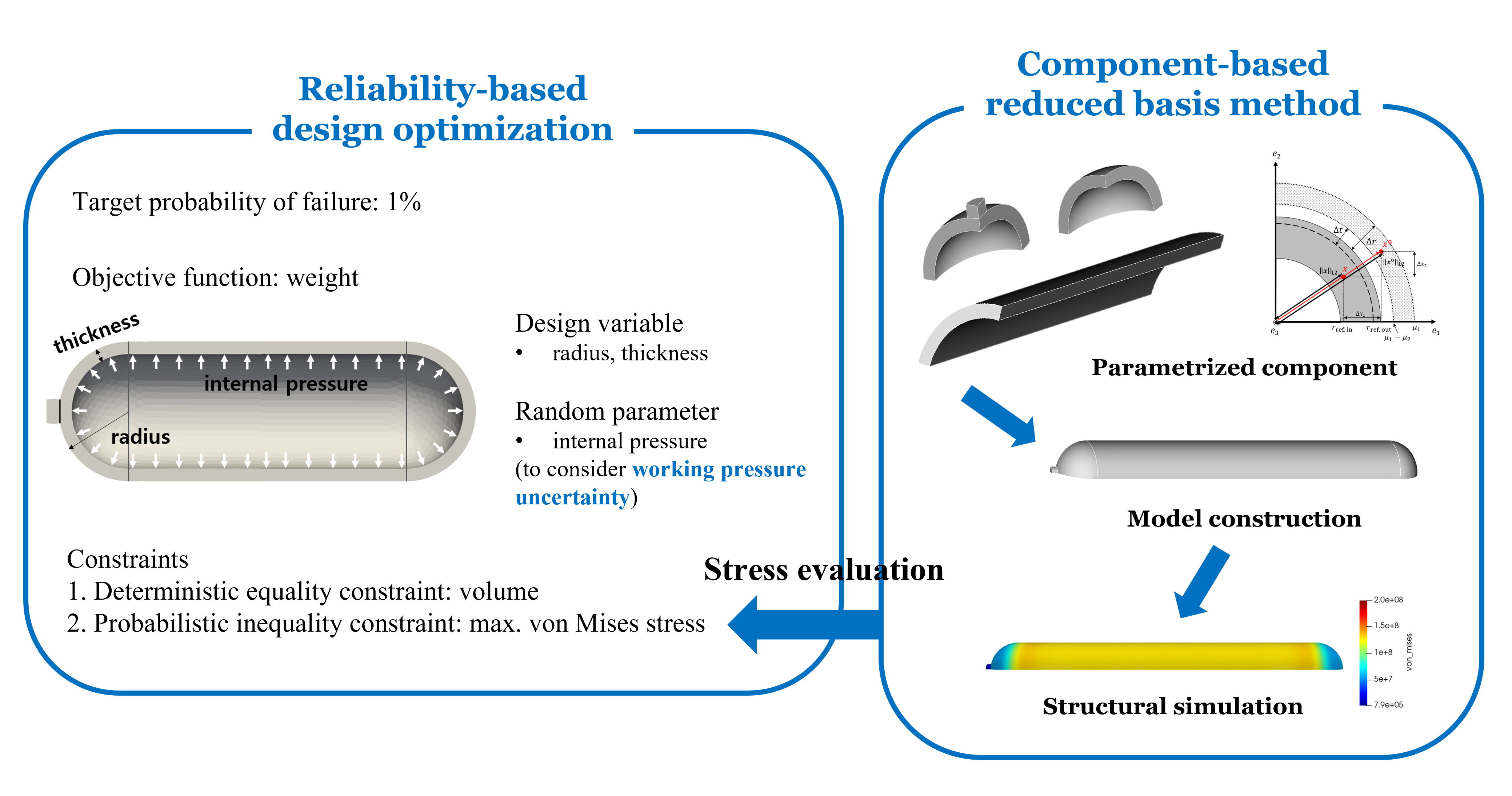

In this study, we perform a design optimization to minimize a weight of a hydrogen vessel under the uncertainty of an operating condition. We set a weight to an objective function by adopting radius and thickness as design variables. In terms of constraints, we set the volume and maximum allowable stress to deterministic equality and probabilistic inequality constraints, respectively. We solve linear elastostatic problems using a component-based reduced basis method to evaluate the maximum stress and thus attained accurate solutions rapidly as compared with using the finite element method. To apply a component-based approach, we divide a vessel model into three simple components and create a linear elastostatic model using geometric and physical parameters. After performing reliability-based design optimization, we achieved a lightweight vessel with target reliability. Moreover, owing to the computational efficiency of the reduced basis solution, we reduced the time to required to achieve an optimal design by realizing efficient simulations.